Bradley Manufacturing produces springs, wire forms and pressed components – specialising in sheet metal fabrication and finishing services, including CNC manufacturing, laser cutting, punching, bending and forming, automated powder coating and sublimation printing.

The third-generation family company also has product testing and electrical assembly capabilities and has recently branched out into making LED light fittings.

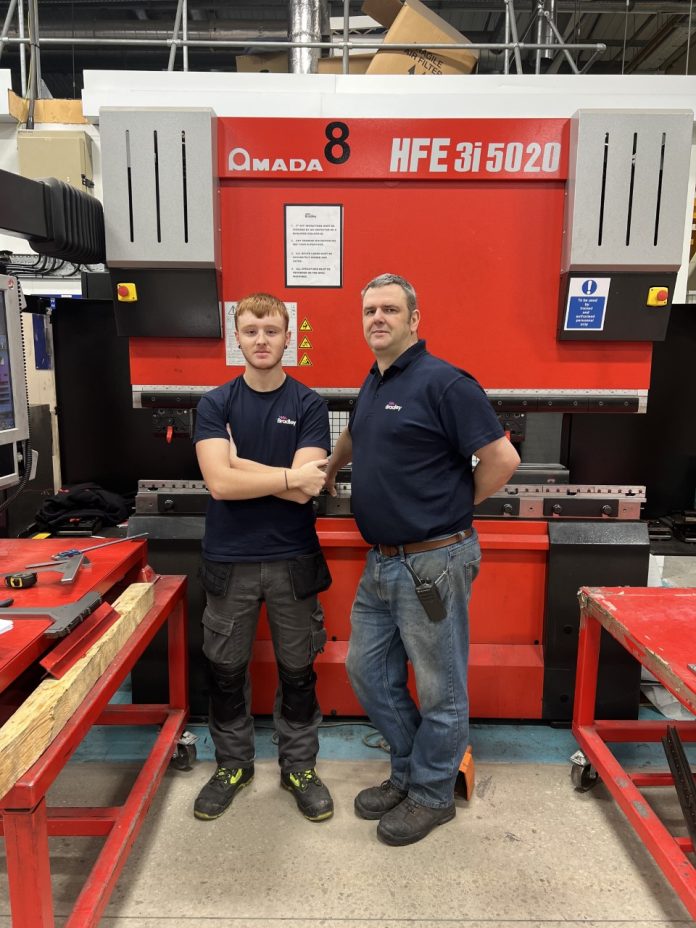

The firm’s 146,000sq. ft state-of-the-art factory in Chadderton, Oldham is home to several engineering apprentices who are currently learning the about the business. The trainees are in different teams and over 12-36 months complete an engineering apprenticeship at level 3 with Rochdale Training.

Tony Holden, apprentice mentor and Spring supervisor, said “I started as an apprentice many years ago with Rochdale Training and I now look after the new trainees. After completing my apprenticeship, I then moved into a full-time skilled role as a flat spring maker. From here I worked my way up within the company. Our business needs young talent to ensure our survival in the future. Trainees gain hands-on experience, while getting paid and full training. Once qualified you can earn up to and above £30,000.

Apprentices are supported through an internal development programme learning new skills from day one. Opportunities to develop and progress are encouraged with full support from the team to move into supervisory and management roles.

Trainees are treated as adults from the day they walk through the door, and given extra responsibility and pay increases, they gain skills in the workplace and promotions during the apprenticeship. I would thoroughly recommend an apprenticeship to any young person; we are currently recruiting and welcome applications from those who want to learn and have a good future career in engineering”.